Engineering Plastics

The company deals into a wide range of engineering plastic compounds for GRE/GRP pipes manufacturer, Automotive, Electrical industry with significant presence in Industrial segment. The company proactively collaborates with OEMs, mould designers & moulders to develop new products to meet their emerging requirements.

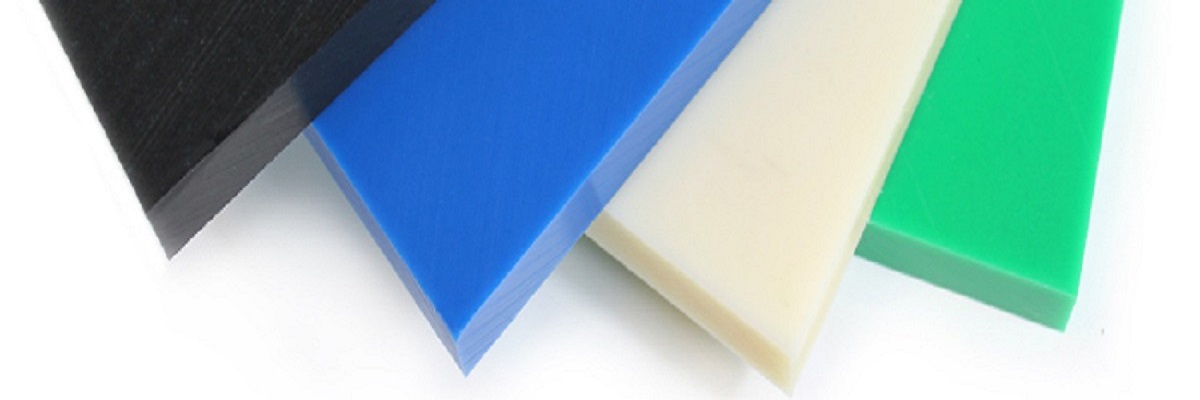

Engineering plastics have gradually replaced traditional engineering materials such as wood or metal in many applications. Besides equalling or surpassing them in weight/strength and other properties, engineering plastics are much easier to manufacture, especially in complicated shapes.

Each engineering plastic usually has a unique combination of properties that may make it the material of choice for some application. For example, polyamides are highly resistant to abrasion.

Benefits of Engineering Plastics:

• Weight reduction • Cost reduction • Electrical insulation • Flame retardancy • Increase in productivity • Hydrolysis resistance • Corrosion resistance • High mechanical strength • Numerous colors can be achieved

About Hi Therm

Hi Therm was founded in 2011 with a philosophy based on helping customers find solutions to problems and a commitment to continuous improvement and service. From that philosophy, Hi Therm has continued to grow and add diverse services and product offerings unlike any other plastics supplier in the industry. Hi Therm understands that speed is essential in today’s competitive marketplace.

4

Offices Worldwide

112

Satisfied Customers

10

Products

35

Awards & Recognitions

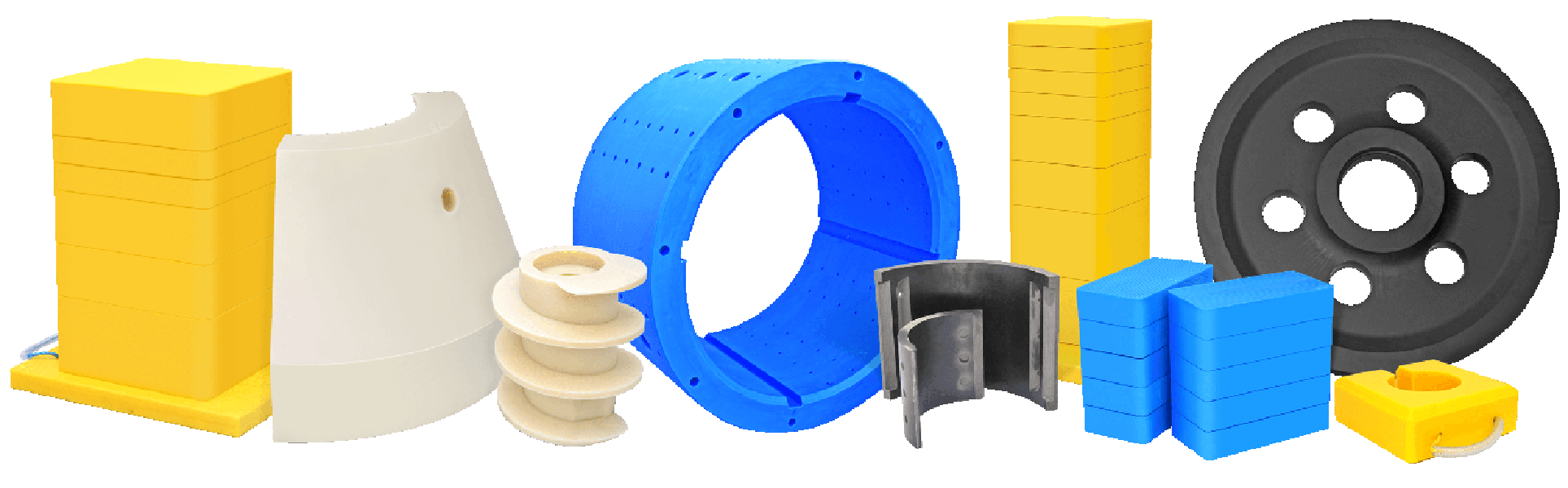

PRODUCTS

Polyamide (PA or Nylon)

The versatility of nylon makes it one of the most widely used engineering thermoplastics. Commercial nylons include nylon 6, nylon 4/6, nylon 6/6, nylon 6/10, nylon 6/12, nylon 11 and nylon 12.

Polycarbonate

PC is an amorphous thermoplastic with a glass transition temperature of approximately 150ºC, allowing it to be used at elevated temperatures.

PTFE tubes & pipes

PTFE is mainly used in wear-resistance & corrosion prevention applications. PTFE components possess many merits. They can provide effective protection against atmospheric acids.

FRP composites

Swiftly evolving composite technologies are central to the production of stronger yet lighter auto components that reduce the overall weight of cars.

Glass epoxy sheet

Based on Epoxy resin and fibreflass reinforcement, various grades of laminates are manufactured to NEMA G-10 and G-11 standards.

Acryllic sheet

Acrylic is a polymer created when giant carbon molecules combine chemically.